As industries around the globe continue to evolve, new leaders emerge with fresh perspectives and innovative ideas. One such leader is Owen McIntire, a visionary whose work has the potential to reshape the industrial landscape. This article delves into McIntire’s philosophy, his contributions to industry, and the implications for the future of various sectors such as manufacturing, technology, and sustainability.

Who is Owen McIntire?

![Owen McIntire and the Future of [Industry] Owen McIntire and the Future of [Industry]](https://d1y8sb8igg2f8e.cloudfront.net/images/25111860895_5639dbc36e_k.2e16d0ba.fill-1200x630.jpg)

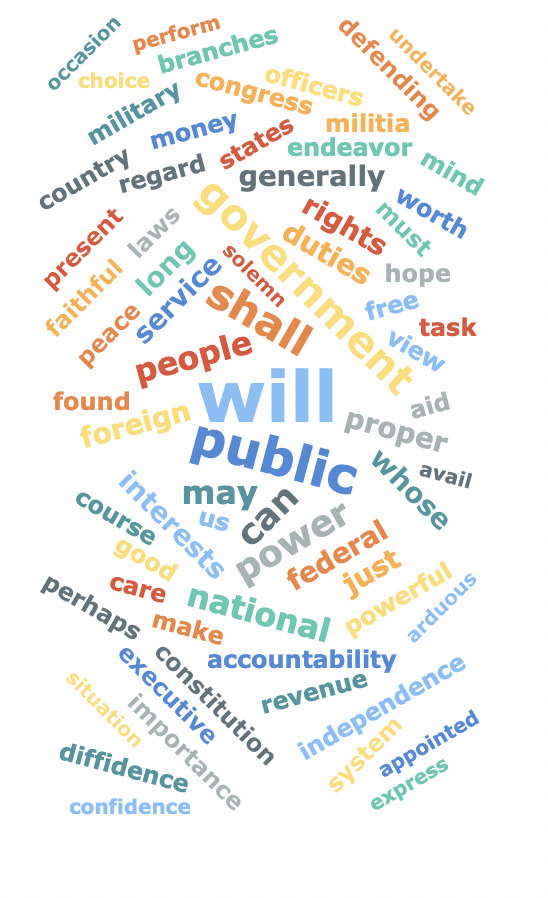

Owen McIntire is a prominent figure in the realm of industrial innovation. With a background in engineering and business management, he has spent decades analyzing and improving manufacturing processes. McIntire’s approach is characterized by a commitment to integrating advanced technologies into traditional industries, thereby enhancing productivity and sustainability.

His work has been recognized in various forums, including industry conferences and academic publications, where he has shared insights on how industries can adapt to changing market demands and technological advancements.

The Intersection of Technology and Industry

One of the cornerstones of McIntire’s vision is the integration of technology into industrial processes. He advocates for the adoption of Industry 4.0—a term that encompasses the current trend of automation and data exchange in manufacturing technologies. This includes the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics.

Key Components of Industry 4.0

- IoT Integration: Connecting machines and devices to the internet for real-time data exchange and monitoring.

- Artificial Intelligence: Utilizing AI to analyze data and optimize production schedules, maintenance, and supply chain logistics.

- Advanced Robotics: Employing robots for tasks ranging from assembly to quality control, enhancing efficiency and safety.

- Big Data Analytics: Leveraging data analytics for informed decision-making, predictive maintenance, and market trend analysis.

McIntire posits that by embracing these technologies, industries can not only increase output but also minimize waste and reduce their carbon footprint. For example, companies such as Siemens and General Electric have successfully implemented smart factories that utilize IoT and AI to streamline operations. This not only improves efficiency but also leads to significant cost savings.

Sustainability: A Non-Negotiable Future

As climate change becomes an increasingly pressing issue, sustainability has risen to the forefront of industry discussions. McIntire emphasizes that the future of industry must prioritize sustainable practices, integrating environmental responsibility into core business strategies.

Strategies for Sustainable Industry

- Renewable Energy Adoption: Transitioning to renewable energy sources such as solar and wind to power industrial operations.

- Waste Reduction Initiatives: Implementing practices that aim to reduce waste, such as recycling and reusing materials.

- Green Supply Chains: Collaborating with suppliers who prioritize sustainability, thus creating a more eco-friendly supply chain.

- Product Lifecycle Management: Designing products with their entire lifecycle in mind, from production to disposal, to minimize environmental impact.

For instance, Unilever has successfully integrated sustainability into its supply chain, achieving a significant reduction in its greenhouse gas emissions. McIntire’s focus on these practices highlights a crucial shift in industry priorities, where profitability and responsibility go hand in hand.

The Role of Workforce in the Future of Industry

As the industrial landscape changes, so does the nature of the workforce. McIntire advocates for upskilling and reskilling programs to prepare workers for the future. The rise of automation and AI demands a workforce that is adaptable and equipped with new skill sets.

Essential Skills for the Future Workforce

- Technical Proficiency: Familiarity with advanced technologies and tools used in modern manufacturing.

- Data Literacy: The ability to analyze and interpret data to make informed decisions.

- Problem-Solving Skills: Critical thinking abilities to address challenges arising from automation and technology integration.

- Collaboration and Communication: Working effectively in diverse teams, often in virtual settings.

Companies like Amazon and Google are already investing in workforce development to ensure their employees are prepared for the jobs of tomorrow. McIntire believes that fostering a culture of continuous learning will be essential for industries to thrive in the future.

Case Studies: Real-World Applications of McIntire’s Vision

To better understand the implications of Owen McIntire’s vision, let’s explore a few case studies that exemplify how companies are implementing his ideas.

Case Study 1: Tesla and Renewable Energy

Tesla has been at the forefront of the electric vehicle revolution, but the company’s commitment to sustainability extends beyond cars. Tesla’s Gigafactories are designed to produce batteries and energy products using renewable energy sources, significantly reducing the carbon footprint associated with traditional manufacturing. This aligns with McIntire’s vision of a sustainable industrial future.

Case Study 2: Siemens’ Digital Factory

Siemens has invested heavily in creating a digital factory that integrates IoT and AI. By utilizing digital twins—virtual simulations of physical entities—Siemens optimizes resource allocation and enhances production efficiency. This innovative approach illustrates McIntire’s emphasis on technology integration in manufacturing.

Case Study 3: Unilever’s Sustainable Living Plan

Unilever’s Sustainable Living Plan aims to decouple its growth from its environmental footprint while increasing its positive social impact. This initiative includes sourcing 100% of its agricultural raw materials sustainably and enhancing the livelihoods of millions. Such strategies demonstrate the alignment with McIntire’s focus on sustainability as a core business principle.

Challenges Ahead: Navigating the Transition

While the future of industry appears promising under the guidance of visionaries like Owen McIntire, several challenges remain. Transitioning to a more integrated, sustainable, and technologically advanced industrial landscape requires overcoming barriers such as:

- Resistance to Change: Organizations may struggle with the cultural shift required to adopt new technologies and practices.

- Investment Costs: Initial capital investment for new technologies can be a significant hurdle for smaller companies.

- Skill Gaps: Bridging the gap between current workforce skills and those needed for the future can be a daunting task.

- Regulatory Challenges: Navigating regulations around sustainability and technology adoption may slow down progress.

Addressing these challenges will require collaboration among industry leaders, policymakers, and educational institutions to create a more adaptable and skilled workforce.

Conclusion: Embracing Change for a Sustainable Future

Owen McIntire’s vision for the future of industry is one that embraces technological advancement, sustainability, and workforce development. As industries evolve, the integration of advanced technologies and sustainable practices will not only enhance efficiency but also ensure a more responsible approach to production.

By learning from successful case studies and addressing the challenges ahead, industries can navigate the complexities of this transition. The future may be uncertain, but with leaders like McIntire paving the way, it promises to be innovative, sustainable, and prosperous.