When it comes to flooring, the finishing touches are just as important as the initial installation. One of the crucial yet often overlooked components is the T-molding track. This small but significant piece serves as a transition between different flooring types or between areas with different heights. Choosing the right T-molding track can enhance the aesthetics of your space, improve functionality, and prolong the life of your flooring. In this article, we will explore the various types of T-molding tracks, their applications, and how to choose the right one for your flooring needs.

What is T-Molding?

T-molding is a type of transition strip that connects two areas of flooring, typically where two different materials meet. It is shaped like the letter “T” and is installed over the joint between the two flooring surfaces. T-molding is commonly used with laminate, hardwood, tile, and vinyl flooring. Its primary functions include:

- Providing a smooth transition between different flooring types.

- Covering expansion gaps required for certain flooring materials.

- Enhancing the overall appearance of the space.

- Protecting the edges of the flooring from wear and tear.

Types of T-Molding Tracks

Understanding the different types of T-molding tracks available on the market is essential in ensuring you select the most suitable one for your flooring project. The following are the most common types:

1. Wood T-Molding

Wood T-molding is ideal for hardwood and laminate floors. It is typically made from the same material as the flooring, allowing for a seamless look. Wood T-molding is available in various finishes and stains, making it easy to match with existing decor. However, it may not be suitable for areas with high humidity, as wood can warp or swell.

2. Metal T-Molding

Metal T-molding is a robust option, often made from aluminum or brass. This type is ideal for high-traffic areas and provides excellent durability. Metal T-molding is also resistant to moisture, making it suitable for kitchens and bathrooms. However, it may not blend as seamlessly with wood or laminate flooring.

3. Vinyl T-Molding

Vinyl T-molding is a flexible and cost-effective choice for transitioning between vinyl and other flooring types. Its flexibility allows it to accommodate slight height differences, making it perfect for uneven surfaces. Additionally, vinyl T-molding comes in various colors and styles, enabling homeowners to find the perfect match.

4. Composite T-Molding

Composite T-molding combines different materials, often including wood fibers and PVC. This type offers the aesthetic appeal of wood while providing moisture resistance. Composite T-molding is suitable for both indoor and outdoor use, making it a versatile option for many homeowners.

Factors to Consider When Choosing T-Molding

When selecting the right T-molding track for your flooring, several factors must be taken into account to ensure you make the best decision. Here are some key considerations:

1. Flooring Material

The type of flooring you have will greatly influence your choice of T-molding. For instance, if you have hardwood flooring, a wood T-molding will provide a more cohesive look, while metal or vinyl might be better suited for tile or vinyl flooring.

2. Height Differences

If there are noticeable height differences between the two flooring surfaces, you’ll need a T-molding that can accommodate that variance. For example, if one flooring is thicker than the other, opting for a T-molding with a higher profile may be necessary to provide a smooth transition.

3. Traffic Levels

Consider the level of foot traffic that area will experience. High-traffic areas may require more durable materials, such as metal or composite, to withstand the wear and tear over time.

4. Aesthetic Preferences

The visual aspect of the T-molding is also important. Choose a color and finish that complements your flooring and overall décor. For instance, if you are aiming for a modern look, sleek metal T-molding may be more appropriate than traditional wood.

5. Installation Method

Different T-molding tracks have varying installation methods. Some may require adhesive, while others come with a track system for easy installation. Consider your DIY skills or whether you will hire a professional before making a selection.

Installation Process for T-Molding

Installing T-molding is relatively straightforward, though the exact process may vary depending on the type of T-molding you choose. Here is a general guide to help you with installation:

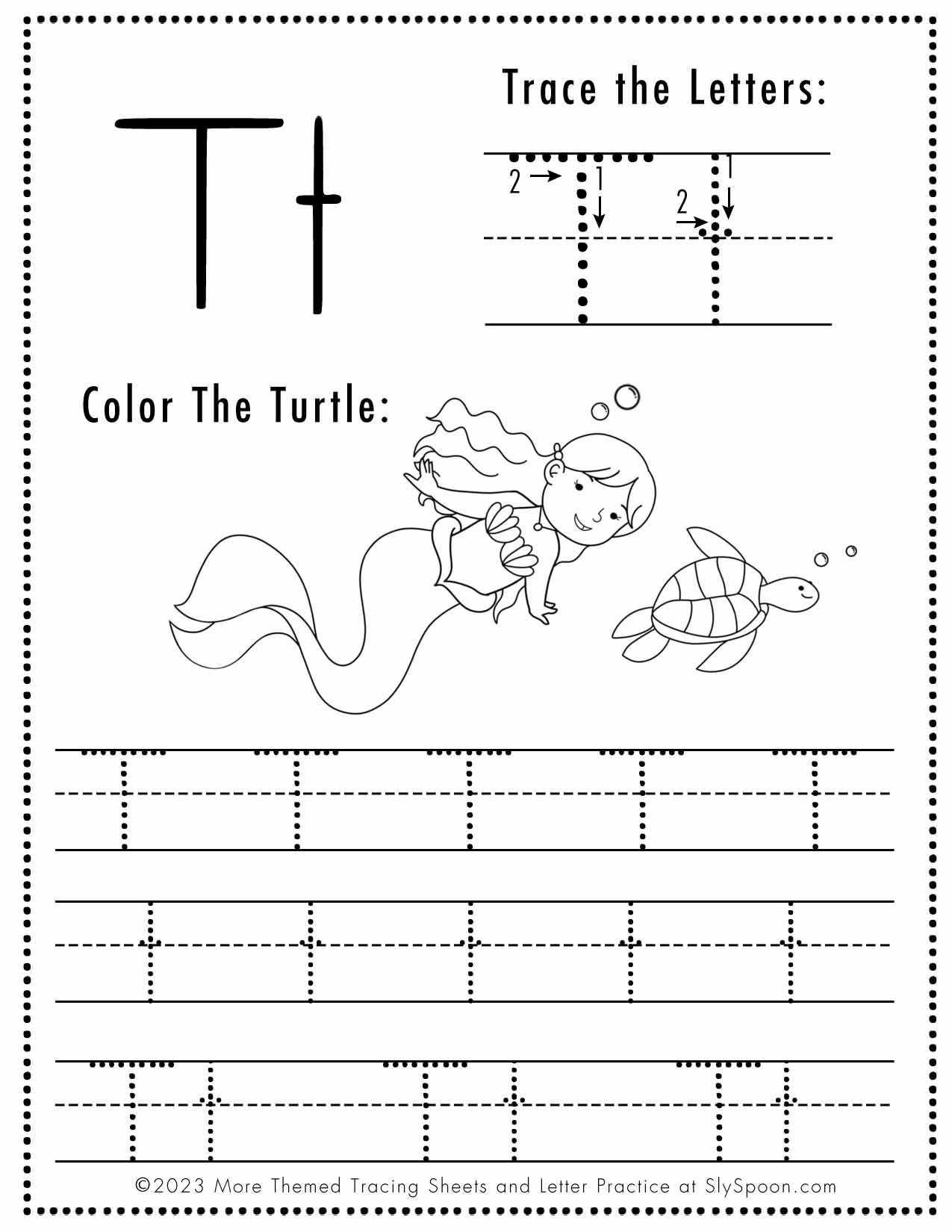

Step 1: Measure the Area

Start by measuring the length of the area where the T-molding will be installed. This will help you determine how much material you need to purchase.

Step 2: Prepare the Subfloor

Ensure that the subfloor is clean and dry. Remove any debris or old adhesive that may interfere with the installation.

Step 3: Cut the T-Molding

Using a miter saw, cut the T-molding to the required length. If the area has corners or angles, ensure that your cuts are precise to maintain a neat appearance.

Step 4: Install the T-Molding

Depending on the type of T-molding, apply adhesive or place it into the track system. Press down firmly to ensure a secure fit.

Step 5: Allow for Expansion

Leave a small gap between the T-molding and the flooring to allow for expansion and contraction, especially in areas with fluctuating temperatures or humidity levels.

Case Studies and Statistics

According to a study conducted by the National Wood Flooring Association, installing the correct transition strips can increase the lifespan of flooring by 25% or more. In one case, a homeowner who opted for high-quality metal T-molding in their kitchen reported a significant reduction in wear and tear on the flooring compared to areas without adequate transition strips.

Another case study involving a commercial space highlighted the importance of choosing durable T-molding. A retail store that installed vinyl T-molding saw a marked decrease in maintenance costs, as the transition strips helped protect the flooring from damage caused by high foot traffic.

Choosing the right T-molding track for your flooring is essential for both aesthetic and functional purposes. By understanding the various types of T-molding available, considering factors such as flooring material and traffic levels, and following a straightforward installation process, you can enhance the beauty and longevity of your floors. Remember that investing in quality T-molding pays off in the long run, protecting your flooring and contributing to the overall appeal of your space. Whether you’re renovating your home or setting up a new commercial space, the right T-molding choice can make a world of difference.